Efficient drainage is critical for urban and industrial infrastructure. Box Pallets, U-Drain Pallets and Header Equipment form the foundation of modern drainage systems, ensuring smooth water flow and preventing flooding. Their structural design, durability and installation efficiency make them indispensable in stormwater management. This article explores their applications, benefits and innovations.

Box/U-Drain Pallets and Headers in Drainage Systems

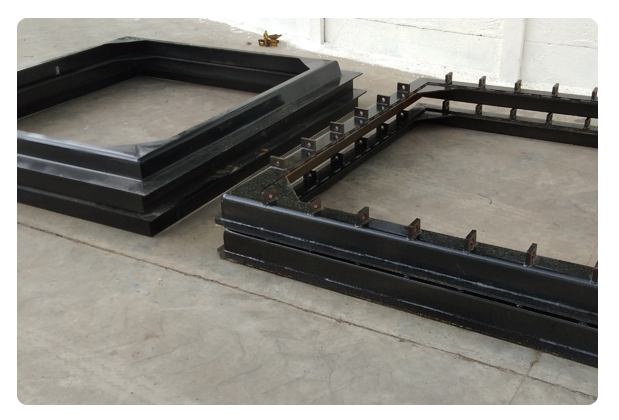

Box Pallets and U-Drain Pallets support drainage structures by ensuring proper water flow and load-bearing capacity. Headers enhance the stability of drainage channels, improving performance in stormwater and wastewater systems.

Key Functions

- Directs water efficiently to prevent stagnation.

- Enhances the durability of drainage systems.

- Reduces erosion and structural damage.

- Supports heavy loads in industrial applications.

Their role in modern urban planning is crucial, particularly in flood-prone regions.

How Box/U-Drain Pallets Contribute to Stormwater Management

Stormwater drainage requires efficient water redirection to avoid urban flooding. Box Pallets and U-Drain Pallets help manage runoff by:

- Providing a structured pathway for excess water.

- Preventing waterlogging in city streets.

- Reducing soil erosion caused by uncontrolled water flow.

- Supporting stormwater retention and groundwater recharge.

Municipalities and developers rely on these components for long-term drainage solutions.

Materials Used in Manufacturing Box/U-Drain Pallets & Headers

The choice of material determines the strength, longevity and cost-effectiveness of drainage components.

Common Materials

- Concrete - High durability, load-bearing capacity and long lifespan.

- Steel - Ideal for heavy-duty applications, resisting extreme conditions.

- Plastic Composites - Lightweight, corrosion-resistant and easy to install.

Each material offers unique benefits based on project needs and environmental conditions.

How to Choose the Right Box/U-Drain Pallet & Header for Your Project?

Selecting the right box pallet and header equipment depends on:

Key Considerations

- Load Requirements - Assess the weight the drainage system must support.

- Environmental Conditions - Consider exposure to chemicals, temperature changes and water volume.

- Installation Complexity - Choose a system that aligns with the project timeline and workforce capabilities.

- Long-Term Maintenance - Opt for materials that require minimal upkeep.

Understanding these factors ensures optimal drainage performance and cost efficiency.

Innovations in Box/U-Drain Pallet and Header Design for Improved Efficiency

Advancements in engineering and technology have enhanced the performance of drainage components.

Modern Innovations

- Precast Concrete Designs - Faster installation with increased durability.

- Smart Drainage Systems - Integration with sensors for real-time water flow monitoring.

- Lightweight Composite Materials - Reduces installation costs and improves efficiency.

These innovations ensure that drainage solutions keep pace with evolving urban needs.

Installation Best Practices for Box/U-Drain Pallets and Headers

Proper installation is critical for ensuring the longevity and performance of drainage systems.

Installation Steps

- Site Preparation - Level the ground and ensure proper drainage slopes.

- Pallet Placement - Align and secure pallets for structural integrity.

- Header Installation - Fit headers for additional stability and support.

- Sealing & Finishing - Use quality sealants to prevent leakage and erosion.

- Testing & Inspection - Conduct water flow tests to verify efficiency.

Following these steps minimizes installation errors and enhances drainage performance.

Challenges in Designing and Manufacturing Box/U-Drain Pallets & Headers

While these components are essential, manufacturers face several challenges.

Common Issues

- Material Costs - High-quality materials increase production expenses.

- Customization Needs - Unique project specifications require tailored solutions.

- Durability vs. Weight - Balancing strength with easy installation remains a challenge.

Solutions

- Using advanced materials to optimize weight and strength.

- Implementing automated production for precision.

- Developing modular systems for adaptable installation.

Overcoming these challenges leads to better drainage solutions.

Custom Box/U-Drain Pallets and Headers: Tailoring Solutions for Unique Drainage Needs

Not all projects fit standard drainage solutions. Custom Box Pallets and U-Drain Pallets provide flexibility for specialized applications.

Custom Design Benefits

- Supports varying load capacities.

- Matches specific drainage layouts.

- Reduces unnecessary material usage.

Customization ensures each project achieves maximum efficiency and durability.

Box/U-Drain Pallets vs. Traditional Drainage Systems

Traditional drainage methods, such as open ditches and perforated pipes, are less efficient than modern pallet-based systems.

Comparison Overview

| Feature | Box/U-Drain Pallets | Traditional Systems |

| Installation Speed | Faster due to modular design | Time-consuming |

| Load-Bearing Capacity | High | Low |

| Durability | Long lifespan | Requires frequent maintenance |

| Efficiency | Directs water effectively | Prone to blockages |

Box and U-Drain Pallets offer superior efficiency and longevity compared to outdated drainage methods.

Load-Bearing Capacity of Box/U-Drain Pallets and Headers

Load-bearing capacity is a crucial factor in infrastructure projects.

Factors Influencing Load Capacity

- Material Strength - Concrete and steel offer superior load support.

- Design Structure - Reinforced frameworks increase durability.

- Installation Method - Proper anchoring prevents shifting under pressure.

Selecting the right load capacity ensures safety and long-term structural integrity.

Maintenance and Durability of Box/U-Drain Pallets and Headers

Regular maintenance extends the lifespan of drainage components.

Maintenance Tips

- Periodic Cleaning - Removes debris and prevents blockages.

- Surface Inspections - Identifies cracks and wear early.

- Reinforcement Checks - Ensures load-bearing strength remains intact.

A proactive maintenance approach reduces repair costs and enhances system efficiency.

Innovative Manufacturing Processes for Box/U-Drain Pallets and Headers

Advancements in production technology are improving drainage component quality.

Modern Manufacturing Techniques

- Automated Casting - Ensures consistent quality.

- Precision Molding - Reduces material waste.

- Laser Cutting & CNC Machining - Enhances design accuracy.

These methods create stronger, longer-lasting drainage solutions.

FAQs - Box Pallets & U-Drain Pallets

Box Pallets provide structural support and ensure efficient water flow in drainage networks.

U-Drain Pallets offer improved water direction, higher durability and faster installation compared to traditional systems.

Concrete, steel and composite plastics are commonly used, each offering different benefits based on project needs.

Yes, manufacturers offer custom designs to meet unique load, size and environmental requirements.

AI-driven water flow monitoring, precision molding and automated casting are improving pallet efficiency and durability.

Read More Articles on Box Pallets & U-Drain Pallets

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES