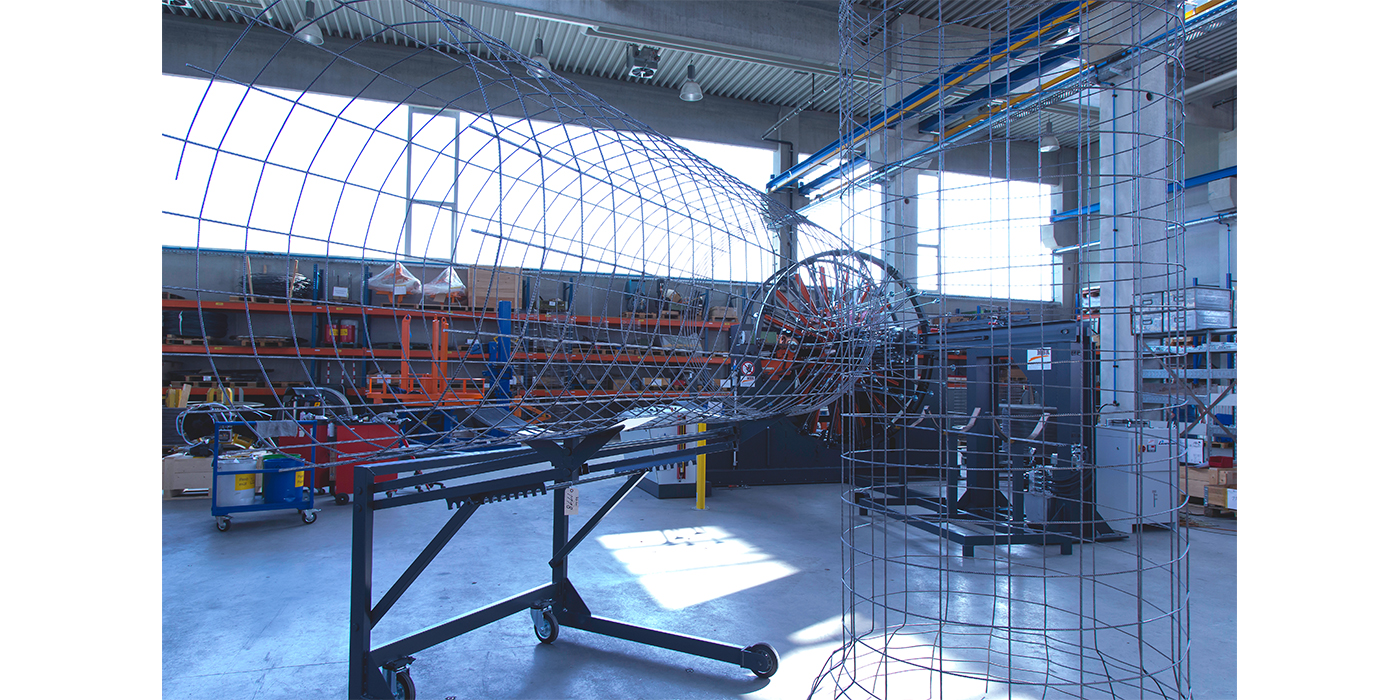

The evolution of cage welding technology has transformed the way reinforcement structures are manufactured. With the introduction of pneumatic and automated systems, cage welding machines have become more efficient, precise and cost-effective. These advancements reduce manual intervention, optimize production speed and enhance the quality of manhole cages, reinforcement cages and structural supports used in concrete construction.

This article explores how pneumatic and automated systems improve the performance of cage welders, making modern cage welder machines more reliable and productive.

The Role of Pneumatic Systems on Cage Welding Machines

Faster Wire Handling and Placement

Pneumatic controls allow automatic cage welding machines to move wires with precision and speed. This eliminates the need for manual adjustments, reducing errors and improving production rates.

Efficient Clamping and Holding Mechanisms

Maintaining a firm grip on wires during welding is critical. Pneumatic clamping ensures:

- Secure positioning of wires without deformation.

- Adjustable pressure to accommodate different cage sizes.

- Consistent contact between welding points for stronger reinforcement.

Controlled Welding Pressure

Pneumatic systems regulate welding force, ensuring each weld is uniform and structurally sound. This results in:

- Improved durability of manhole cages and other reinforcement structures.

- Reduced defects caused by over-welding or insufficient bonding.

Lower Maintenance and Longer Machine Life

Pneumatic components experience less wear compared to mechanical alternatives. With fewer moving parts, cage welding machines benefit from:

- Reduced maintenance costs.

- Longer service life.

- Less downtime for repairs.

How Automation Improves Cage Welding Technology?

Automated Wire Feeding and Positioning

Modern cage machines use servo-driven motors to automatically align and feed wires, ensuring:

- Faster cycle times.

- Precise wire spacing for structural integrity.

- Minimal material waste.

Programmable Welding Parameters

Automatic cage welding machines allow operators to pre-set welding sequences, ensuring:

- Consistency in every reinforcement cage.

- Quick adjustments for different project requirements.

- Optimized energy consumption during the welding process.

Real-Time Monitoring and Error Detection

Automation enables real-time tracking of the welding process, detecting and correcting issues such as:

- Misaligned wires.

- Weak weld spots.

- Overheating or irregular current flow.

Increased Safety and Reduced Manual Labor

With automation, operators no longer need to handle high-temperature welding processes manually. This reduces risks related to:

- Burns from welding sparks.

- Injuries from heavy wire movement.

- Fatigue from repetitive tasks.

Key Benefits of Pneumatic and Automated Cage Welding Systems

- Higher productivity due to faster welding cycles.

- Consistent weld quality with controlled automation.

- Reduced material waste through precise wire placement.

- Lower operational costs by minimizing labor requirements.

- Longer machine lifespan with less mechanical strain.

Applications of Pneumatic and Automated Cage Welding Machines

Manhole Cage Manufacturing

The production of manhole cages requires precise spacing and strong welds. Pneumatic clamping and automated wire feeding ensure accurate reinforcement structures for durable concrete manholes.

Reinforcement Cages for Concrete Pipes

Concrete pipes need reinforcement cages with uniform strength. Cage welding machines equipped with automation guarantee reliable results, reducing weak points in concrete pipe reinforcements.

Large-Scale Infrastructure Projects

Bridges, tunnels and high-rise buildings require reinforcement cage machinery capable of handling high-volume production. Automated cage welders improve efficiency while meeting structural specifications.

When investing in a cage welding machine manufacturer should evaluate:

- Production capacity for meeting output requirements.

- Level of automation to ensure efficient workflow.

- Pneumatic system reliability for precise pressure control.

- Software integration for real-time process adjustments.

Investing in an automatic cage welding machine ensures better productivity, reduced costs and long-term reliability.

FAQs About Cage Welding Machine

Pneumatic systems enable faster wire handling, precise clamping and controlled welding pressure, leading to higher efficiency and durability.

Automation improves wire feeding, welding accuracy and production speed, reducing manual labor and material waste.

Yes, programmable cage welders allow for quick adjustments to produce various reinforcement cage sizes.

It detects welding inconsistencies, misalignment and weak spots, ensuring better quality control.

Industries involved in manhole cage production, concrete pipe reinforcement, bridge construction and tunnel development benefit the most.

Conclusion

The integration of pneumatic and automated systems in cage welding machines has significantly improved the efficiency, precision and safety of reinforcement cage production. These advancements allow for faster production, lower operational costs and consistent weld quality.

For manufacturers in concrete reinforcement industries, investing in cage welder with advanced pneumatic and automation technology is essential for meeting modern construction demands. By adopting these innovations, companies can streamline production, improve quality and enhance profitability.

Read More Articles on Cage Welding Machines

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES