Concrete pipes play a crucial role in infrastructure, from drainage systems to sewage lines. The process by which these pipes are produced largely impacts their durability, cost, and time to market. Two primary methods used in the manufacturing of concrete pipes are drycast and wet cast moulding processes. Each of these methods has its unique features, advantages, and limitations. This article will compare drycast pipe moulds and wet cast pipe moulds, discussing their differences, benefits, and best-suited applications.

What is Drycast Pipe Moulding?

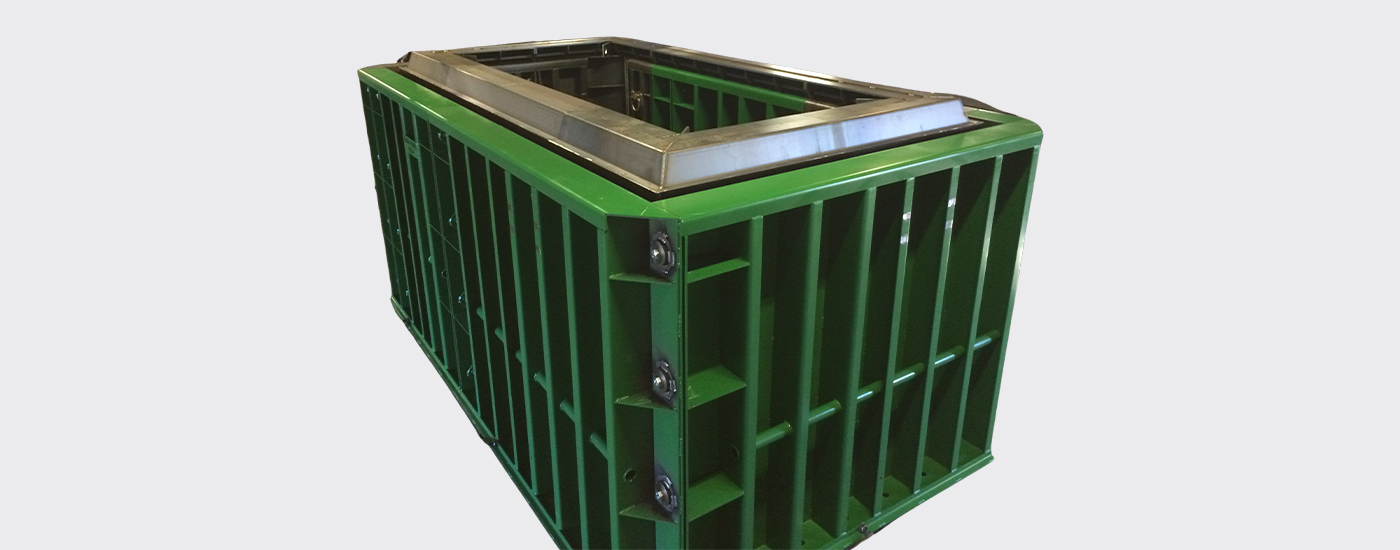

The drycast process (sometimes referred to as the no-slump concrete process) involves using a very low water-to-cement ratio, creating a zero-slump mixture. In this process, pipe moulds are filled with a stiff concrete mixture that compacts easily. The concrete is then consolidated using inner cor vibration and spigot joint is formed through hydraulic pressing & rocking. The pipe is removed from the inner cor and taken directly to the curing area by crane, where the outer jacket is stripped from the pipe. This method is highly mechanized, making it popular for large-scale production.

Advantages of Drycast Pipe Moulding:

- High-Speed Production: Drycast moulds are ideal for mass production. A significant advantage of this process is the speed with which concrete pipe moulds can be used and reloaded, often allowing manufacturers to produce multiple pipes per day.

- Minimal Curing Time: Due to the low water content, drycast pipes can be stripped from their moulds and handled immediately after formation. This drastically reduces the time spent waiting for the concrete to set.

- Precision in Shape and Size: The highly compacted mixture ensures that the final product comes out with precise dimensions, which is vital for ensuring uniformity in large-scale infrastructure projects.

- Sustainability: Since there is less water used in the process, the drycast method is often seen as more eco-friendly.

Limitations of Drycast Pipe Moulding:

- Surface Finish: While functional, drycast concrete pipes tend to have a rougher surface finish compared to wet cast pipes, making them less suitable for certain aesthetic applications.

- Limited Complex Shapes: Drycast moulding is ideal for simple, repetitive shapes like cylindrical pipes, square or rectangular boxes. It may not be the best fit for more intricate designs or shapes.

What is Wet Cast Pipe Moulding?

The wet cast process involves using a higher water-to-cement ratio, resulting in a more fluid mixture that can be poured into a mould. The concrete mixture in wet casting has a greater slump, making it easier to fill the mould and achieve a more detailed finish. The process is generally slower compared to drycast but is used in applications that demand a smoother finish or custom shapes.

Advantages of Wet Cast Pipe Moulding:

- Superior Surface Finish: Wet cast pipes have a much smoother and aesthetically pleasing surface due to the higher water content, making this process ideal for visible or decorative concrete applications.

- Flexibility in Shape: Wet cast moulding allows for greater flexibility in terms of the types of pipe moulds and drain moulds that can be used. Manufacturers can produce complex and non-standard shapes that would be difficult to achieve with drycast.

- Stronger Bonding: The higher water content often results in better cement bonding, making wet cast pipes more durable in certain conditions, especially when exposed to aggressive environments.

Limitations of Wet Cast Pipe Moulding:

- Slower Production Speed: Wet cast moulding generally takes longer to set and cure. The curing time is essential before the pipes can be demoulded and handled, meaning fewer pipes can be produced in the same time frame compared to drycast.

- Higher Costs: Due to the longer curing times and additional labor required, wet cast pipes are often more expensive to produce.

Applications Best Suited for Each Method

- Drycast Pipe Moulding is commonly used in large-scale production where speed and uniformity are prioritized, such as for sewer systems, culverts, and stormwater drainage. The quick production process and minimal curing time make it ideal for high-volume projects with standard specifications.

- Wet Cast Pipe Moulding, on the other hand, is better suited for architectural projects, decorative elements, and custom infrastructure components that require intricate designs and smoother finishes. It’s commonly used for precast concrete products where aesthetics and surface quality are important.

Which Process is Right for You?

When deciding between drycast and wet cast processes, the choice depends on the specific requirements of the project. If speed, durability, and uniformity are the primary concerns, drycast pipe moulds offer a clear advantage. Pipe mould manufacturers often recommend this method for large-scale infrastructure work. On the other hand, if the project demands superior aesthetics or custom shapes, wet cast pipe moulds may be the more appropriate choice.

Integrating Advanced Pipe Mould Equipment

Both processes can be optimized with modern Pipe Mould Equipment, which enhances productivity and precision. For example, automated systems in the drycast process ensure that concrete pipe moulds are filled and compacted more efficiently, reducing labor costs and ensuring consistency. For wet cast operations, modern pipe moulds with easy demoulding system and built-in heating systems can accelerate curing times, bridging the gap in production speeds between the two methods.

Conclusion

Both drycast and wet cast pipe moulding methods have their unique advantages, and the right choice depends largely on the specific application. Drycast pipe moulding is ideal for high-volume production with a focus on durability and cost-efficiency. Wet cast pipe moulding, however, excels in delivering aesthetically superior and highly customizable products. As the technology evolves, advances in concrete pipe moulds and pipe mould equipment are continuously improving the efficiency and versatility of both processes.

FAQs About Drycast Pipe Mould and Wet Cast Pipe Mould

Drycast uses low water content and is faster, whereas wet cast involves higher water content for a smoother finish but takes longer to cure.

Drycast pipe moulding is more cost-effective for large-scale production due to its speed and lower labor requirements.

While possible, wet cast is generally slower and more suited for custom or decorative applications rather than mass-produced infrastructure components.

Yes, drycast pipes generally have a rougher surface finish compared to the smoother, more detailed finish of wet cast pipes.

Wet cast pipe moulding is better suited for intricate designs and custom shapes, offering more flexibility than drycast.

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES