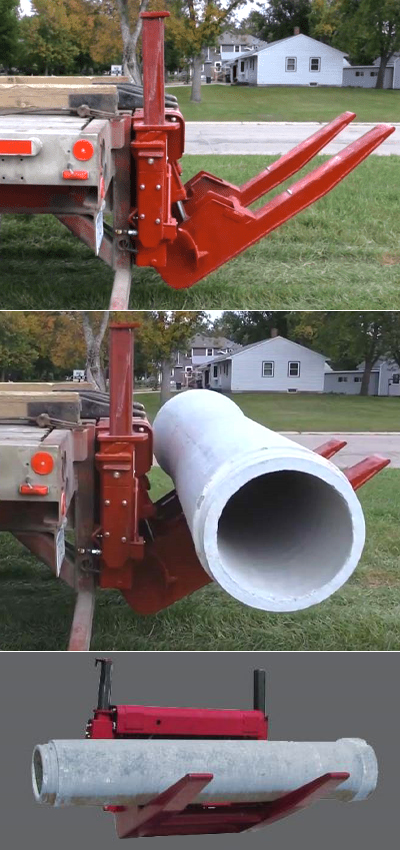

Handling heavy concrete pipes during production, transportation, and installation requires specialized equipment to ensure safety and efficiency. AHCT’s LT-1400 and LT-2500 pipe lifting turning yokes are designed to lift, transport, and tilt large, cured concrete pipes with diameters of up to 4216 mm and weights as heavy as 25 tons. While these yokes significantly improve productivity, it is crucial to follow best safety practices to avoid accidents, injuries, or equipment damage.

This guide provides essential safety tips for using AHCT’s LT-1400 and LT-2500 yokes, focusing on handling heavy concrete pipes in a safe and controlled manner.

1. Conduct a Thorough Equipment Inspection Before Use

Before operating the LT-1400 or LT-2500 yoke, it is essential to inspect the equipment for any signs of wear, damage, or malfunctions. Check the following:

- Yoke components: Ensure that all parts, including chains, hooks, and clamps, are in good condition and securely attached.

- Hydraulics (if applicable):Verify that the hydraulic system (if integrated) is functioning properly, with no leaks or signs of wear.

- Lifting points: Check that the lifting points on the yoke are free from cracks or deformities.

- Crane compatibility:Ensure that the crane or lifting machine being used is compatible with the yoke and can handle the weight of both the yoke and the concrete pipe machine.

Regular maintenance and timely inspections are key to ensuring the safety of your lifting operations.

2. Verify Pipe Specifications Against Yoke Capacity

Each model of AHCT’s lifting yokes is designed for specific pipe sizes and weights. Always ensure that the concrete pipe being handled is within the capacity of the yoke. The LT-1400 can handle pipes with diameters between 700 mm and 2500 mm and up to 14 tons in weight. The LT-2500, on the other hand, accommodates pipes with diameters of up to 4216 mm and weights up to 25 tons.

Lifting pipes beyond the yoke's rated capacity can result in equipment failure, pipe damage, and potentially dangerous situations for workers. Always double-check the pipe’s dimensions and weight before proceeding.

3. Ensure Proper Rigging and Lifting Technique

Correct rigging is crucial for the safe handling of heavy concrete pipes manufacturing. Improper rigging can lead to shifting, dropping, or tilting the pipe unintentionally. To ensure safety:

- Center the load: The yoke must be centered directly over the pipe’s center of gravity to prevent unbalanced lifting. An off-center load can swing dangerously and put undue stress on the yoke and crane.

- Use appropriate rigging materials: Ensure the use of strong, well-maintained slings, hooks, and chains rated for the load being lifted.

- Secure the pipe:The yoke should securely grip the pipe without causing damage. Ensure that the pipe is held firmly in place before starting the lift.

Improper rigging is one of the most common causes of accidents in lifting operations, so taking the time to secure everything properly is essential.

4. Clear the Area Before Lifting or Turning

The area around the lifting and turning operation must be free from obstacles, equipment, and personnel. A designated safety zone should be established, marked, and enforced to ensure no unauthorized personnel enter the area during lifting or turning.

Maintaining a clear and controlled work area helps reduce the risk of accidents caused by unexpected obstructions or distractions.

- Alert personnel:Communicate with the team before starting the lift to ensure everyone is aware of the operation and clear of the working area.

- Avoid distractions: Only authorized, trained personnel should be allowed in the vicinity of the operation, and they should remain focused on the task at hand.

5. Control the Speed of Lifting and Turning

When lifting and turning heavy concrete pipes, it’s important to move slowly and steadily. Rushing the process can lead to sudden swings, uneven tilting, or loss of control over the pipe. Always follow these guidelines:

- Lift gradually: Raise the pipe slowly to reduce the risk of swinging. Sudden or jerky movements can destabilize the load.

- Tilt carefully:When using the LT-1400 or LT-2500 to tilt the pipe, make sure the rotation is slow and controlled. Sudden tilts can cause the pipe to shift, increasing the risk of damage or accidents.

- Use proper hand signals: If the crane operator has limited visibility, a spotter should be used to provide clear and standardized hand signals for communication.

Controlling the speed of lifting and turning operations ensures that the load remains stable throughout the process.

6. Avoid Lifting in Adverse Weather Conditions

Wind and rain can make lifting operations more dangerous. High winds can cause the load to swing unpredictably, while rain can make the work area slippery and affect the operator's visibility. It’s best to avoid lifting in such conditions, or if necessary, to proceed with extreme caution:

- Monitor wind speeds:If wind speeds exceed a certain threshold (depending on the size of the pipe and yoke), consider postponing the lift.

- Check visibility: Ensure that the operator has clear visibility during the lift. If rain or fog impairs visibility, pause the operation until conditions improve.

Operating in adverse weather conditions should only be done when absolutely necessary, and even then, extra precautions must be taken.

7. Train Personnel in Safe Operation Procedures

Only trained and certified personnel should be operating the LT-1400 and LT-2500 yokes. Workers involved in lifting operations should receive training on the following:

- Proper use of the yoke:Understanding how to attach, lift, transport, and tilt concrete pipes using the yoke.

- Emergency procedures:Knowing what to do in case of equipment failure or other emergencies.

- Communication skills:Effective communication between the crane operator, riggers, and ground personnel is crucial for safe operations.

Ensuring that everyone involved in the lifting operation is properly trained reduces the risk of accidents and equipment damage.

8. Use Spotters to Assist with Lifting and Turning

For large and heavy concrete pipes, the crane operator may not always have full visibility of the load and surrounding area. Designating spotters can help ensure that the operator has the necessary guidance to complete the lift safely. Spotters should:

- Provide clear signals: Use standardized hand signals or communication devices to guide the crane operator during the lift.

- Monitor the area: Spotters can help ensure that the work area remains clear and alert the operator to any potential hazards.

- Assist with tilting: During tilting operations, spotters can help ensure that the pipe rotates smoothly and remains stable throughout the process.

Having extra eyes on the operation helps prevent errors and ensures better overall safety.

9. Use the Right Crane and Lifting Equipment

Ensure that the crane or lifting equipment used in conjunction with the LT-1400 or LT-2500 yoke is appropriately rated for the load. The crane should be able to handle the combined weight of the pipe, yoke, and any rigging materials without exceeding its safe working load (SWL).

Additionally, the lifting equipment should be inspected regularly and maintained to prevent malfunctions or failures during operations.

10. Ensure Proper Storage of the Yoke After Use

After completing a lifting operation, it’s important to store the lifting yoke properly to ensure it remains in good condition for future use. Proper storage practices include:

- Clean the yoke:Remove any dirt, dust, or debris from the yoke after use to prevent wear and corrosion.

- Inspect for damage: Conduct a post-use inspection to check for any signs of wear or damage that need to be repaired before the next use.

- Store in a dry place:Ensure the yoke is stored in a dry, safe location to prevent rusting and deterioration.

Proper maintenance and storage will extend the lifespan of the yoke and ensure it performs reliably in future operations.

Conclusion:

AHCT’s LT-1400 and LT-2500 lifting turning yokes are invaluable tools for handling large concrete pipes efficiently. However, safety must always be the top priority when operating these heavy-duty machines. By following these best practices, you can minimize the risks associated with lifting and turning heavy pipes, ensuring that both your workers and your equipment remain safe.

Proper training, regular equipment inspections, and a well-organized work environment are key to safe and successful lifting operations. With the right precautions in place, AHCT’s lifting turning yokes can significantly enhance both productivity and safety in concrete pipe manufacturing.

FAQs - Lifting and Turning Heavy Concrete Pipes

The LT-2500 yoke can handle concrete pipes weighing up to 25 tons, with pipe diameters ranging from 1400 mm to 4216 mm.

Before using the LT-1400 yoke, inspect the equipment, verify pipe dimensions and weight, ensure proper rigging, and clear the area of unauthorized personnel.

Lifting turning yokes reduce manual handling, allowing for more precise and controlled lifting, tilting, and transportation of heavy concrete pipes, minimizing the risk of accidents.

Spotters assist by guiding the crane operator, ensuring the load remains stable, and helping to monitor the work area for potential hazards during the lift.

While it is possible to use the yokes in mild adverse conditions, it is safer to avoid lifting operations in high winds or heavy rain to reduce the risk of accidents.

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES