In the world of modern infrastructure, concrete pipes play a vital role in various construction projects, especially in drainage, sewage systems, and water management. However, manufacturing and handling these large, heavy pipes can be a time-consuming and labor-intensive process. To address this challenge, companies are increasingly turning to advanced tools like pipe lifting and turning yokes. AHCT’s lifting turning yokes, particularly the LT-1400 and LT-2500 models, are designed to streamline the handling of cured concrete pipes. These yokes improve productivity in concrete pipe manufacturing by reducing manual handling and significantly increasing production speed.

In this article, we’ll explore how these innovative lifting devices enhance efficiency and safety in the production and transportation of concrete pipes.

The Challenge of Handling Large Concrete Pipes

Concrete pipes, especially those used in large infrastructure projects, can be massive. With outer diameters ranging from 700 mm to over 4000 mm, and weights as heavy as 25 tons, moving these pipes manually or with traditional equipment can be challenging, time-consuming, and dangerous. Improper handling can lead to damaged pipes, delays in production, and potential injuries to workers.

Before the introduction of advanced lifting yokes like AHCT’s LT-1400 and LT-2500, pipe manufacturers relied heavily on cranes, slings, and manual labor to lift, transport, and tilt these heavy components. Not only was this inefficient, but it also increased the risk of human error and equipment damage. With the arrival of pipe lifting turning yokes, this entire process has become much more streamlined, allowing manufacturers to increase productivity while reducing risks.

What Are Pipe Lifting Turning Yokes?

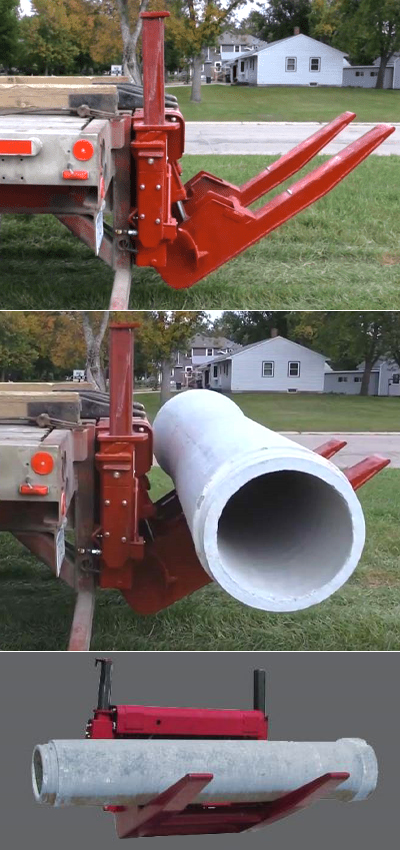

Pipe lifting turning yokes are specialized lifting devices designed to safely and efficiently handle large concrete pipes during and after the manufacturing process. They allow operators to lift, transport, and tilt pipes that have already cured, providing precise control over the movement and positioning of the pipes.

AHCT’s LT-1400 model is engineered to handle pipes with diameters between 700 mm and 2500 mm, with a maximum weight capacity of 14 tons. The LT-2500 model is designed for even larger pipes, with diameters ranging from 1400 mm to 4216 mm, and can support pipes weighing up to 25 tons. These yokes are essential in both the manufacturing plant and on construction sites, ensuring safe and efficient handling of large, heavy pipes.

1. Reducing Manual Handling to Enhance Safety and Efficiency

One of the most immediate benefits of using lifting turning yokes is the reduction of manual handling. Moving large, heavy pipes manually requires significant manpower and is inherently risky. Workers are exposed to potential accidents, and the chances of pipe damage are high if the pipes are not handled correctly.

With the LT-1400 and LT-2500 yokes, the process becomes far safer and more efficient. These yokes are designed to attach securely to the pipes, allowing operators to lift and transport them with minimal effort. The risk of injuries from manual lifting is virtually eliminated, and the pipes are moved with precision, reducing the likelihood of damage. This means fewer workplace accidents and fewer rejected pipes, both of which enhance productivity in the long run.

2. Streamlining the Manufacturing Process

Lifting turning yokes play a crucial role in speeding up the entire manufacturing process. In traditional setups, moving a large concrete pipe from the casting station to the curing area, and then to the storage yard, can be a slow and cumbersome process, often requiring several workers and different pieces of equipment. Each time a pipe is moved manually or with outdated methods, it slows down production, creating bottlenecks.

AHCT’s yokes significantly reduce the time it takes to move these pipes. The LT-1400 and LT-2500 models allow operators to easily lift and transport pipes with the help of a crane or other lifting machinery. The precision with which the yokes grip the pipes means that they can be transported more quickly and efficiently, with less downtime between steps in the production process.

For large-scale concrete pipe manufacturers, this can make a significant difference. The faster a pipe can be moved from one stage to the next, the more pipes can be produced in a day. By eliminating slow, labor-intensive steps, the overall production output increases, which is critical for meeting project deadlines and maximizing profitability.

3. Increasing Production Speed by Simplifying Pipe Tilting

Tilting pipes is another challenging aspect of concrete pipe manufacturing, especially when dealing with massive pipes weighing several tons. In many situations, the pipes need to be tilted during transportation, storage, or installation. Manually tilting these pipes is not only difficult but can also be dangerous.

AHCT’s pipe lifting turning yokes simplify the tilting process. Both the LT-1400 and LT-2500 models allow operators to tilt the pipes safely and with great precision. The yokes are designed to rotate the pipes in a controlled manner, allowing them to be tilted as needed without risking damage to the pipe or the surrounding equipment. This feature is particularly useful during the installation phase, as pipes can be quickly and easily aligned in the correct position.

The ability to tilt pipes effortlessly reduces the time needed to complete various steps in the manufacturing and installation process. This, in turn, leads to faster production cycles and more efficient use of resources, contributing to higher overall productivity.

4. Handling Larger Pipes with the LT-2500 for Bigger Projects

As infrastructure projects grow in size and complexity, the need for larger concrete pipes is increasing. The LT-2500 lifting turning yoke is specifically designed to handle these massive pipes, with diameters of up to 4216 mm and a weight capacity of 25 tons. This makes the LT-2500 an ideal choice for manufacturers who are producing pipes for large-scale projects such as tunnels, bridges, and massive drainage systems.

By providing a tool capable of handling such large pipes, AHCT allows manufacturers to take on bigger projects without the need for additional equipment or complicated setups. This increases the flexibility and capacity of the manufacturing plant, allowing it to produce a wider range of products to meet diverse project needs.

5. Improving Overall Workflow and Reducing Downtime

Another key advantage of AHCT’s lifting turning yokes is their contribution to improved workflow and reduced downtime. In a manufacturing environment, any delay in moving or handling materials can lead to a ripple effect, slowing down the entire production process. Traditional methods of handling large pipes are often slow and prone to causing such delays.

By integrating the LT-1400 and LT-2500 into the production line, manufacturers can significantly reduce these delays. The yokes allow for faster, more reliable transportation and handling of the pipes, ensuring that each stage of the manufacturing process runs smoothly. Less time is wasted waiting for pipes to be moved or adjusted, meaning that production can continue at a steady pace with minimal interruptions.

Conclusion

AHCT’s LT-1400 and LT-2500 lifting turning yokes are game-changers in the concrete pipe manufacturing industry. By reducing manual handling, improving safety, streamlining the manufacturing process, and increasing production speed, these yokes help manufacturers boost productivity and efficiency. Their ability to handle pipes of varying sizes and weights, tilt pipes with precision, and reduce downtime makes them indispensable tools for any concrete pipe manufacturer looking to enhance their production capabilities.

As infrastructure projects continue to demand larger, heavier pipes, the importance of tools like AHCT’s lifting turning yokes will only grow. These devices not only make the production process faster and safer but also enable manufacturers to meet the evolving needs of the construction industry with greater ease and efficiency.

FAQs - Pipe Lifting Turning Yokes

The LT-2500 can handle concrete pipes weighing up to 25 tons, making it ideal for large-scale projects.

Lifting turning yokes reduce manual handling, minimizing the risk of accidents and injuries, and ensuring that pipes are moved and tilted with precision.

The LT-1400 model is designed to lift and tilt pipes with outer diameters ranging from 700 mm to 2500 mm.

By automating the lifting, transporting, and tilting processes, the yokes reduce the time and manpower needed to handle pipes, allowing for faster production cycles.

Large infrastructure projects require heavy concrete pipes, and lifting turning yokes like the LT-2500 are designed to handle these massive components efficiently, ensuring that projects stay on schedule and within budget.

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES