In modern construction, effective drainage systems are essential to ensure the longevity and safety of infrastructure. roadways, bridges and utilities. These precast concrete moulds help manufacturers create precise, durable and consistent drainage structures, such as U-drains and box culverts, that serve critical functions in water management and utility infrastructure.

In this article, we will explore the role of U-drains mould in precast concrete production, the advantages of using precast moulds for drainage systems and how U-drains making machines contribute to more efficient construction processes. By understanding how these systems work, construction professionals can better utilize precast concrete moulds to meet the growing demand for reliable drainage solutions.

The Significance of Precast Concrete in Drainage Systems

Precast concrete is a construction method where concrete is poured into a reusable form and cured in a controlled environment. The result is a high-strength product that is then transported and installed at construction sites. This method is widely used for drainage systems due to its many advantages.

Advantages of Precast Concrete in Drainage Construction:

- Durability: Precast concrete gets stronger over time and is more resistant to harsh weather conditions, making it ideal for long-lasting drainage solutions.

- Reduced Maintenance: Precast concrete elements, like U-drains, may require little or no maintenance during their lifetime, providing a more cost-effective and reliable drainage solution.

- Time Efficiency: The use of precast moulds allows for faster production and delivery compared to traditional on-site casting methods. This minimizes project timelines and delays.

- Quality Consistency: Precast concrete is produced in controlled conditions, ensuring that every product is uniform in quality and finish. This consistency is critical in ensuring the reliable functioning of drainage systems.

Key Benefits for Drainage Systems:

- Longer Service Life: Precast concrete products, including U-drains mould, are designed to withstand environmental stresses and last for decades.

- Fewer Construction Disruptions: The reduction of noise, dust and wastage associated with on-site casting makes precast concrete a more efficient and environmentally friendly option.

The Role of U-Drains Mould in Precast Concrete Drainage Systems

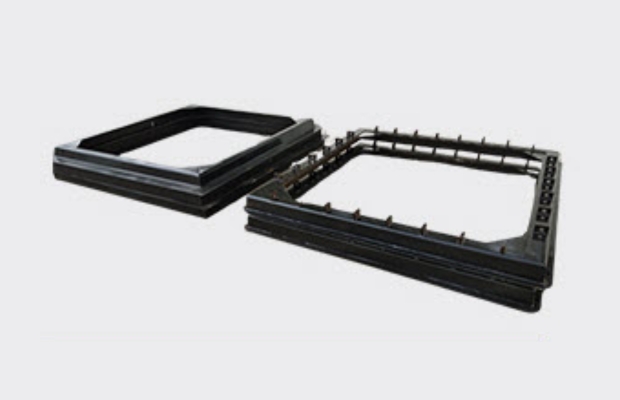

U-drains are essential components used in drainage systems for highways, stormwater management and wastewater control. These concrete elements are shaped using U-drains mould to create uniform, durable and precisely dimensioned products. These moulds are integral to producing high-quality drainage components that fit seamlessly into their intended locations.

U-Drains Mould: Key Features

- Shape and Design: The U-drain mould is specifically designed to create the characteristic U-shaped channels needed for drainage systems. These moulds ensure that every piece is uniform in shape and dimension, promoting proper water flow and efficient installation.

- Material Strength: U-drains moulds are designed to produce products that are strong enough to withstand the pressure from the surrounding soil and traffic load while allowing water to flow efficiently.

- Customization: Some precast concrete mould manufacturers offer customized U-drains moulds to cater to unique project requirements, including adjustments in size, shape or strength.

How U-Drains Mould Contributes to Efficient Drainage Systems?

- Reliable Water Flow: The precise design of U-drains moulds ensures that the concrete products facilitate efficient water flow without obstruction. Properly molded U-drains prevent issues like water stagnation and ensure the smooth transit of water in drainage systems.

- Compatibility with Other Infrastructure: U-drains mould can be used to create complementary pieces, like end caps and connectors, ensuring that the drainage system remains structurally sound and cohesive.

The Role of Precast Moulds in the U-Drain Production Process

Precast moulds are essential tools in the creation of drainage systems, especially when working with complex shapes and specific product requirements. U-drains moulds are just one example of the many moulds used in this process.

How Precast Moulds Improve Efficiency in U-Drain Production?

- Consistent Quality: With precast moulds, manufacturers can produce drainage components with consistent dimensions and structural integrity, which reduces defects and ensures reliable functionality.

- Faster Turnaround Times: Precast allows products to be made in parallel with other project stages. This reduces the need for time-consuming on-site casting and expedites the construction process.

- Optimized for Mass Production: Precast moulds like U-drains mould are designed for efficient production at scale, enabling manufacturers to meet the high demand for drainage systems in large infrastructure projects.

U-Drains Making Machine: Revolutionizing the Concrete Production Process

A U-drains making machine is an essential tool for producing U-drains in an automated fashion. These machines ensure that each piece of drainage equipment is made quickly, efficiently and with precise quality control. The use of advanced machines has allowed manufacturers to scale their production capabilities and meet the growing demand for drainage systems in urban planning and infrastructure development.

Key Benefits of U-Drains Making Machines:

- Automation: These machines automate the casting process, allowing for quicker turnaround times and reducing the need for manual labor, leading to increased productivity.

- Precision: U-drains making machines ensure that every unit produced meets exact specifications, reducing defects and the need for rework.

- Cost-Effectiveness: By streamlining the production process and reducing labor costs, U-drains making machines contribute to more economical manufacturing, which is essential for large-scale infrastructure projects.

Impact on the Industry:

- Increased Efficiency: The automation of production with U-drains making machines ensures faster lead times, helping meet the deadlines for large construction projects.

- Improved Quality: With precise control over dimensions and material distribution, these machines help maintain the high quality of drainage products over time.

The Future of U-Drains Mould and Precast Concrete Solutions

The future of U-drains mould in precast concrete production looks promising, with continuous innovations in mould design, material technology and manufacturing processes. As urbanization increases and infrastructure projects expand, the demand for high-quality, efficient drainage solutions will continue to rise.

Emerging Trends in U-Drains Moulds and Concrete Production:

- Technological Advancements: The integration of automation and digital technologies into the design and production of U-drains mould will further improve efficiency and precision.

- Sustainable Materials: As the construction industry evolves, there may be a greater emphasis on using sustainable materials in the production of U-drains moulds and precast products.

- Customization and Flexibility: With the demand for more specialized and adaptable drainage solutions, mould manufacturers will likely focus on offering more customizable options for U-drains moulds.

FAQs

A U-drains mould is a specialized form used to create U-shaped concrete products that are primarily used in drainage systems for stormwater management and wastewater control.

U-drains making machines automate the production of U-drains, ensuring high precision, reduced labor costs and faster production times.

U-drains moulds ensure that concrete drainage systems, such as pipes and culverts, are manufactured to the correct specifications.

When selecting a U-drains mould supplier, it's important to consider their experience, material quality and customization capabilities.

Conclusion

U-drains mould plays an essential role in the precast concrete industry by ensuring the efficient production of high-quality drainage systems. By providing precision, durability and versatility, these moulds help manufacturers produce reliable concrete products that are integral to infrastructure development. The rise of U-drains making machines and improved precast concrete moulds has revolutionized the production process, making it faster, more efficient and more cost-effective.

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES