Manhole construction is a critical component of urban infrastructure, enabling access to underground drainage systems, sewage networks, and utilities. Traditionally, manholes in many parts of India have been constructed using bricks and mortar, a labor-intensive and time-consuming process. However, as the country’s infrastructure demands grow, there is a pressing need for faster, more efficient, and standardized construction methods. Enter wetcast forms for manholes a modern solution offered by companies like AHCT. These forms are designed to create high-quality manholes in compliance with Indian Standards (IS 17725: 2022), reducing labor, time, and costs, while ensuring consistency and durability.

In this article, we will explore the key advantages of wetcast forms over traditional construction methods and why they represent the future of manhole construction in India.

The Traditional Brick-and-Mortar Method: Time-Consuming and Laborious

In many regions of India, manholes are still constructed using bricks and mortar, a technique that has been in use for decades. While effective, this method comes with several challenges:

- Labor-Intensive: Constructing a manhole with bricks and mortar requires skilled labor, with workers manually placing and aligning each brick. The process is labor-intensive and demands significant manpower.

- Time-Consuming:Building a manhole this way is slow, often taking days or even weeks to complete, especially in large-scale projects. This can cause delays in overall infrastructure development.

- Inconsistent Quality: Brick-and-mortar construction is subject to human error. Variations in the placement of bricks or the quality of materials can lead to inconsistencies in the final product, affecting the durability and performance of the manhole.

- Structural Weaknesses: Over time, manholes constructed with bricks and mortar are more prone to wear and tear, especially under heavy traffic loads or harsh environmental conditions, leading to the need for frequent repairs and maintenance.

As India’s urban centers grow rapidly and the demand for robust, long-lasting infrastructure increases, these challenges make the traditional approach less viable for modern projects.

The Rise of Wetcast Forms: A Modern Solution

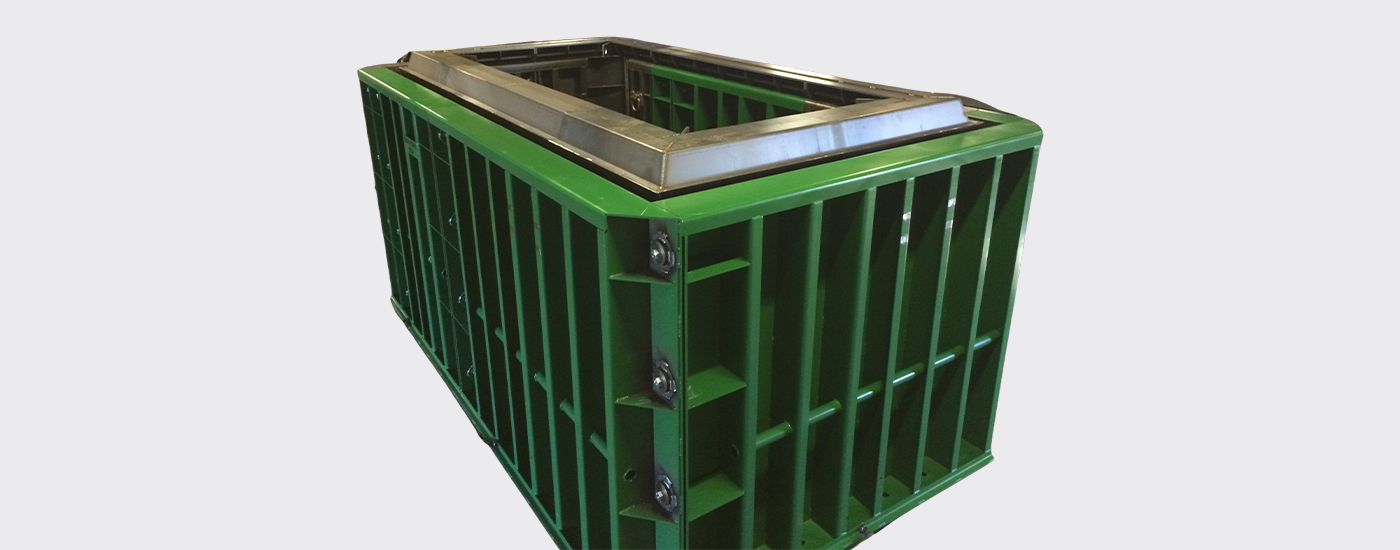

Wetcast forms are precast molds used to create concrete manhole components such as cones, risers, bases, slabs, and joint rings. AHCT, a leader in this technology, offers wetcast forms designed to meet the Indian Standard IS 17725: 2022, which ensures that the manholes produced are consistent in quality and built to last.

Wetcast forms offer numerous advantages that make them the future of manhole construction in India:

1. Significant Time Savings

One of the most critical advantages of using wetcast forms for manholes is the dramatic reduction in construction time. Wetcast forms allow for precasting the manhole components in controlled factory environments, which can then be transported to the construction site and assembled quickly. This eliminates the need for on-site bricklaying and mortar application.

- Rapid Production: Using wetcast forms enables faster production of manhole components, significantly speeding up the construction process. A manhole that would take days to build using bricks and mortar can be completed in a matter of hours with wetcast forms.

- Reduced Project Delays: With quicker assembly times, infrastructure projects can meet tight deadlines, leading to fewer delays in construction schedules.

2. Consistency and Quality Assurance

In infrastructure projects, consistency is key to ensuring long-lasting performance. Wetcast forms provide uniformity in the dimensions and structure of the manhole components, leading to higher quality and better durability.

- Precision Molds:Wetcast forms are designed to exact specifications, ensuring that each component is produced with the same dimensions and strength. This precision reduces variability and the risk of structural weaknesses.

- Indian Standards Compliance: AHCT’s wetcast forms are made in accordance with IS 17725: 2022, ensuring that all manholes meet the strict standards required for public safety and performance. This compliance is essential for projects that need to adhere to national regulations.

- Durability:Wetcast concrete components are highly resistant to environmental factors, heavy loads, and wear and tear, making them more durable than traditional brick-and-mortar manholes.

3. Reduced Labor Requirements

Traditional manhole construction requires a skilled labor force to lay bricks, apply mortar, and ensure structural integrity. Wetcast forms simplify the construction process by automating much of the work.

- Fewer Workers Needed: Wetcast forms can be used by fewer workers, reducing labor costs and the need for a large workforce. This is particularly important in today’s construction industry, where there is often a shortage of skilled labor.

- Simplified Assembly:Since the components are precast, they can be easily assembled on-site with minimal labor. This reduces the potential for human error and speeds up the process, allowing construction teams to focus on other tasks.

4. Cost-Effective Construction

While the initial investment in wetcast forms and precast components may be higher than traditional methods, the long-term benefits make it a cost-effective solution for manhole construction.

- Lower Labor Costs: With fewer workers required and faster construction times, labor costs are significantly reduced.

- Reduced Maintenance: Wetcast concrete manholes are more durable and less prone to damage, reducing the need for frequent repairs and maintenance. This long-term cost savings makes wetcast forms an attractive option for municipalities and private contractors alike.

- Fewer Material Wastage:Wetcast forms produce uniform components, leading to less material wastage during production compared to the variable requirements of brick-and-mortar construction.

5. Versatility in Design and Application

Wetcast forms offer flexibility in design, making them suitable for a wide range of manhole configurations and applications. AHCT provides different types of forms to cater to specific needs:

- Cone Forms: Used for the upper part of the manhole, providing a smooth transition to the access point.

- Riser Forms:These cylindrical forms help adjust the height of the manhole to match the road or ground level.

- Base Forms: The foundation of the manhole, ensuring stability and proper drainage.

- Slab Forms: Used to create the cover slabs for manholes.

- Joint Rings: These ensure proper sealing between manhole components, preventing water ingress and structural weakening.

This versatility allows contractors to adapt the forms to various site conditions and project requirements, making them suitable for a broad range of applications.

6. Enhanced Safety for Workers and Public Infrastructure

Wetcast forms enhance safety not only for workers on construction sites but also for the public who rely on the infrastructure.

- Safer Work Environment:With fewer manual tasks involved, workers are less exposed to common construction hazards such as lifting heavy materials, repetitive motions, and working in confined spaces.

- Increased Structural Integrity: : Precast manholes made with wetcast forms are stronger and less prone to failure, reducing the risk of sinkholes, road damage, or hazardous conditions for the public.

7. Sustainability and Environmental Benefits

As India moves towards more sustainable construction practices, wetcast forms offer several environmental advantages over traditional brick-and-mortar methods:

- Lower Carbon Footprint: Precasting manholes in a controlled environment leads to more efficient use of materials, reducing the overall carbon footprint of the construction process.

- Reduced Waste:Wetcast forms ensure precise measurements and material usage, leading to less waste compared to the excess mortar and bricks that are often discarded in traditional construction.

- Longer Lifespan: Wetcast manholes have a longer lifespan, reducing the need for replacement and further conserving resources over time.

Conclusion:

As India’s infrastructure demands continue to grow, the need for efficient, high-quality, and durable solutions becomes increasingly critical. Wetcast forms are rapidly emerging as the future of manhole construction, offering a faster, safer, and more cost-effective alternative to traditional brick-and-mortar methods. By reducing labor costs, ensuring consistency, and adhering to Indian Standards, wetcast forms provide a modern solution that aligns with the country’s evolving infrastructure needs.

For contractors and municipalities looking to build long-lasting, reliable manholes with minimal delays, wetcast forms represent the future of construction. As more regions in India adopt this technology, we can expect to see faster project completion times, improved infrastructure quality, and reduced environmental impact.

FAQs - Wetcast Forms for Manholes

Wetcast forms are precast molds used to create concrete components for manholes, including cones, risers, bases, slabs, and joint rings, ensuring consistent quality and faster assembly.

Wetcast forms are faster, require less labor, produce higher quality components, and comply with Indian Standards (IS 17725: 2022), making them superior to traditional methods.

Wetcast forms offer time savings, reduced labor costs, consistent quality, durability, versatility in design, and environmental sustainability.

Wetcast forms produce concrete components that are more resistant to environmental factors, heavy loads, and wear and tear, leading to a longer lifespan for manholes.

Wetcast forms for manholes comply with IS 17725: 2022, ensuring they meet the necessary standards for public safety and infrastructure performance.

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES