Handling irregular precast concrete shapes presents unique challenges in the construction industry. These non-standard elements require specialized lifting solutions to ensure safety, efficiency and structural integrity. This article delves into the intricacies of customized lifting solutions, the essential precast lifting accessories designed for irregular precast concrete shapes and solutions for common challenges faced during lifting operations.

Irregular Precast Concrete Shapes: An Overview

Irregular precast concrete shapes deviate from standard geometric forms, featuring complex designs, varying dimensions and unique contours. These elements are often utilized in architectural projects, infrastructure developments and specialized construction applications where standard precast components are insufficient.

Challenges in Lifting Irregular Precast Concrete Elements and Its Solutions

Complex Geometries

Challenge:

Irregular precast shapes often have curves, recesses and non-uniform thicknesses, making it difficult to apply standard lifting methods without risking damage or instability.

Solution:

- Use lifting inserts strategically placed during the casting process to ensure secure lifting points.

- Employ Precast Lifting Loops for flexible and adaptable lifting solutions.

- Utilize yoke lifting equipment to distribute the load evenly across complex geometries.

Uneven Weight Distribution

Challenge:

The asymmetrical nature of irregular precast components leads to uneven weight distribution, complicating the lifting process and increasing the risk of instability or accidents.

To Address:

- Use yoke lifting equipment to balance the load effectively.

- Implement Lifting and Erection Anchors to provide multiple lifting points for even distribution.

- Conduct a structural analysis before lifting to determine optimal anchor placement.

Attachment Point Limitations

Challenge:

Identifying secure and balanced lifting points on irregular shapes is difficult, which can lead to unsafe lifting conditions.

Solution:

- Incorporate Utility Lifting Anchors during the casting process for secure attachment points.

- Use Easy Lift Utility Anchors to allow quick and reliable connection to lifting equipment.

- Apply Lifting Pin Dog Bone Anchors in areas where additional grip is required for safety.

Risk of Concrete Damage During Lifting

Challenge:

Improper lifting techniques or unsuitable accessories can cause cracks or damage to the precast element.

Implement:

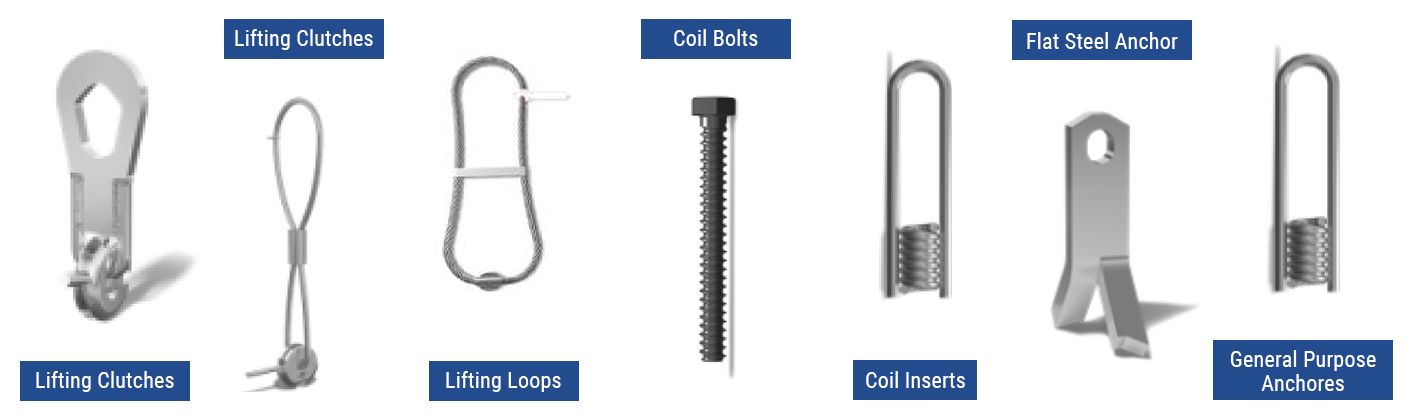

- Use Precast Lifting Clutches to prevent stress concentration on the concrete surface.

- Ensure the use of Dog Bone Lifting Anchors to provide a firm grip and avoid excessive pressure.

- Apply Recess Formers to create proper lifting anchor placements that minimize surface damage.

Safety Risks in Handling Irregular Precast Elements

Challenge:

Unsafe lifting practices can lead to accidents, injuries or structural failures on construction sites.

Solution:

- Follow industry safety guidelines and inspect lifting accessories before use.

- Use Lifting Pin Anchors to provide a secure and balanced lift.

- Train workers on the correct usage of pipe and concrete pipe lifting equipment to prevent mishandling.

Essential Precast Lifting Accessories

In addition to specialized equipment, various lifting accessories play a crucial role in managing irregular precast concrete shapes.

1. Lifting Inserts

Lifting inserts are embedded into the concrete during the casting process, providing secure points for lifting. They are essential for ensuring that the lifting forces are appropriately transferred, reducing the risk of damage.

2. Dog Bone Lifting Anchors

The Dog Bone Lifting Anchor is specifically designed for heavy and irregularly shaped precast elements. Its unique shape offers enhanced load-bearing capacity and stability during lifting operations.

3. Lifting and Erection Anchors

Lifting and Erection Anchors serve dual purposes: facilitating the lifting process and aiding in the accurate positioning of precast elements during assembly. They are indispensable in projects involving complex precast components.

4. Precast Lifting Loops

Precast Lifting Loops offer flexible lifting points, accommodating various lifting angles and positions. They are particularly useful when dealing with irregular shapes that require adaptable lifting solutions.

5. Lifting Pin Dog Bone Anchors

Lifting Pin Dog Bone Anchors combine the features of lifting pins and dog bone anchors, providing a robust solution for handling heavy and irregular precast elements. Their design ensures a secure grip and balanced load distribution.

6. Precast Lifting Clutches

Precast Lifting Clutches are used in conjunction with lifting anchors, allowing for quick and secure attachment during lifting operations. They enhance efficiency and safety, especially when dealing with complex precast shapes.

7. Lifting Pin Anchors

Lifting Pin Anchors are versatile accessories suitable for a range of precast elements. Their straightforward design facilitates easy installation and reliable performance during lifting operations.

Best Practices for Lifting Irregular Precast Concrete Shapes

To ensure safety and efficiency when lifting irregular precast concrete elements, consider the following best practices:

- Conduct Thorough Assessments: Evaluate the weight, geometry and structural integrity of the precast element to determine the appropriate lifting equipment and accessories.

- Use Specialized Equipment: Employ customized lifting solutions such as concrete pipe lifting equipment and yoke lifting equipment designed to handle irregular shapes.

- Implement Secure Attachment Points: Utilize lifting inserts, Utility Lifting Anchors and Easy Lift Utility Anchors to establish reliable lifting points.

- Ensure Even Load Distribution: Apply equipment like yoke lifting equipment and Precast Lifting Loops to distribute weight evenly, minimizing stress on the element.

- Adhere to Safety Standards: Follow industry guidelines and manufacturer instructions when selecting and using lifting accessories to prevent accidents and ensure structural integrity.

FAQs

Customized solutions address the unique challenges of complex geometries and uneven weight distribution, ensuring safe and efficient handling.

Lifting inserts provide secure attachment points within the concrete, reducing the risk of damage and ensuring stability during lifting.

Yoke lifting equipment helps balance the load across multiple lifting points, preventing stress on the precast element.

Precast Lifting Clutches ensure quick and secure attachment of lifting equipment, improving efficiency and reducing lifting time.

Lifting and Erection Anchors provide multiple lifting points, ensuring an even weight distribution and reducing the risk of instability.

Conclusion

Handling irregular precast concrete shapes necessitates the use of customized lifting solutions and specialized accessories. By integrating equipment such as concrete pipe lifting equipment, yoke lifting equipment, Utility Lifting Anchors, Easy Lift Utility Anchors and various lifting accessories, construction professionals can safely and efficiently manage the complexities associated with these unique elements. Adhering to best practices and utilizing the appropriate tools not only enhances safety but also contributes to the successful execution of construction projects involving irregular precast concrete components.

Recent Articles

- The Impact of Advanced Safety and Automation Features in Concrete Pipe Making Machines

- Customized Lifting Solutions for Irregular Precast Concrete Shapes

- The Role of Heat and Humidity in Concrete Curing: A SmartSet Approach

- How Pressure Pipes Machinery Supports Large-Scale Projects?

- Applications of Automated Curing Systems in the Construction Industry

BACK TO ARTICLES

BACK TO ARTICLES