Manhole moulds and box moulds are essential in creating durable and efficient underground structures. They are used in the construction of sewer systems, drainage systems and other critical urban infrastructure. Without high-quality moulds, achieving consistent and reliable manhole structures would be nearly impossible.

This article explores the importance of manhole moulds and box moulds in construction projects. We’ll also cover material selection, manufacturing processes and technological advancements.

Significance of Manhole Moulds in Construction Projects

Manhole systems are essential for underground utilities, providing access for maintenance and inspections. Manhole moulds ensure that these structures are built with precision and durability.

Why are Manhole Moulds Important?

- They provide uniform shapes for efficient underground systems.

- They help in producing durable structures that withstand environmental stress.

- They ensure accuracy in precast concrete manhole production.

A well-designed manhole mould leads to longer-lasting underground systems, reducing repair costs and improving safety.

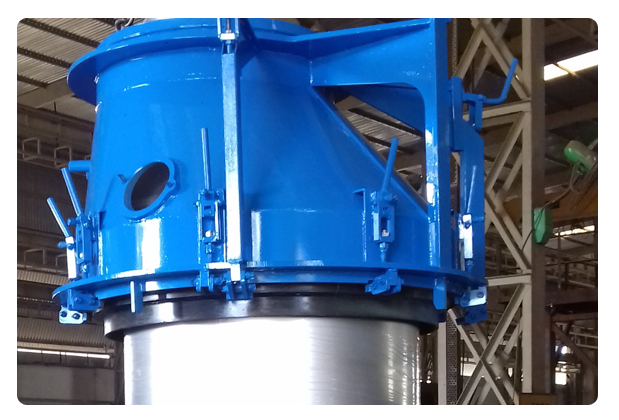

The Manufacturing Process of Manhole Moulds: From Design to Production

The production of high-quality manhole moulds and box moulds follows a detailed process.

1. Design and Prototyping in Manhole Moulds

- Engineers create digital models to ensure precision.

- Prototypes are tested for structural integrity.

2. Material Selection in Manhole Mould

- Steel moulds offer high durability and resistance to wear.

- Aluminum moulds are lightweight and corrosion-resistant.

3. Manhole Moulds Provide Fabrication and Assembly

- CNC machines ensure accuracy in mould production.

- Welded sections are reinforced for longevity.

4. Finishing and Quality Testing in Manhole Moulds

- Moulds undergo surface treatment to improve lifespan.

- Quality checks confirm precision and durability.

Manufacturers of manhole making machines use these steps to ensure reliable production.

Challenges in Producing High-Quality Manhole Moulds and How to Overcome Them

Manufacturers of manhole moulds face several challenges.

Common Issues

- Material defects - Impacts durability and precision.

- Inconsistent dimensions - Results in misalignment during installation.

- Production inefficiencies - Lead to high costs and delays.

Solutions

- Using high-grade raw materials.

- Implementing CNC technology for accuracy.

- Regular quality checks during production.

Efficient manhole producing machines help resolve these challenges.

The Role of Manhole Moulds in Urban Infrastructure Development

Urban areas rely on manhole systems for underground utilities. Manhole moulds play a critical role in maintaining safe and durable structures.

Key Contributions

- Ensuring uniformity in underground utility structures.

- Reducing maintenance costs with durable construction.

- Supporting large-scale urban development projects.

Governments and contractors prefer manhole mould manufacturers who provide high-quality and customizable solutions.

Innovative Materials Used in Manhole and Box Moulds

The material used in manhole moulds and box moulds impacts their lifespan and performance.

- Stainless Steel - Corrosion-resistant and long-lasting.

- Aluminum - Lightweight but strong.

- Plastic - Used for temporary or lightweight applications.

Advanced materials enhance durability and ensure precision in mould production.

Box Moulds: Applications in Different Industries

Box moulds are not limited to construction. They have applications in multiple industries.

Common Applications

- Box Moulds in Construction - Precast concrete blocks, barriers.

- Role of Box Moulds in Automotive - Component moulding for vehicle parts.

- Box Moulds in Packaging - Industrial and commercial containers.

Box mould manufacturers provide tailored solutions based on industry requirements.

How to Choose the Right Box Mould for Your Project?

Box moulds are widely used in precast concrete production for various industrial applications. Choosing the right one depends on material type, dimensions and intended use.

Factors to Consider When Selecting a Box Mould

- Material: Steel and aluminum are common for durability.

- Size: The mould should match the project specifications.

- Surface Finish: A smooth finish ensures better-quality precast structures.

Maintenance and Care for Box Moulds to Ensure Longevity

Proper maintenance extends the lifespan of box moulds.

Maintenance Tips:

- Clean moulds after each use.

- Store in a dry environment to prevent rust.

- Regularly inspect for wear and tear.

Following these steps ensures durability and cost-efficiency.

Key Factors Influencing the Cost of Manhole and Box Moulds

The price of manhole moulds and box moulds varies due to:

- Material quality -Higher-grade materials increase costs.

- Size and complexity - Larger moulds require more resources.

- Manufacturing technology - CNC and automation add precision but also cost.

Investing in high-quality moulds leads to long-term savings.

The Future of Manhole Mould and Box Mould Manufacturing

The manhole mould equipment is evolving with new innovations.

Trends to Watch

- Increased automation in mould production.

- Use of advanced composite materials.

- Improved customization options for diverse applications.

Conclusion

Manhole moulds and box moulds are essential components in modern infrastructure, ensuring the durability and precision of underground utility systems. From manhole producing machines to box mould equipment, the industry continues to evolve with technological advancements, making production more efficient and cost-effective.

Choosing the right manhole mould suppliers or box mould manufacturers is crucial for ensuring high-quality results in construction projects. Whether opting for customized moulds or standard designs, the right selection can significantly impact project efficiency and longevity.

FAQs - Manhole Moulds and Box Moulds Shape Modern Construction

Manhole moulds are used to create durable underground utility access points for sewer, drainage and communication networks.

Consider material, size and application. Steel is ideal for long-term durability, while aluminum is lightweight and easy to handle.

Material selection, precision in fabrication and quality control processes impact the durability and performance of manhole moulds.

With proper maintenance, high-quality steel moulds can last for years without degradation.

Box moulds are widely used in construction, automotive and industrial packaging sectors.

Read More Articles on Manhole Moulds and Box Moulds

- Demand and Process for Manhole Production System

- Karibic Revolutionizing Manhole Production with Fully Automatic Systems

- Karibic Technology Advantages in Manhole Ring and Neck Production

- Karibic & Mammut for Manhole Rings/Bases and Box Culverts: Revolutionizing Prefabricated Concrete Products

- KARIBIC’s Manhole Ring Production Process

- Why Wetcast Forms are the Future of Manhole Construction in India?

- The Role of Precast Manhole Systems in Modern Infrastructure Development

Recent Articles

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

- How to Match Your Concrete Pipe Making Machine with the Perfect Drycast Mould?

- How to Keep Concrete Pipe Machine and Drycast Moulds in Top Condition? Maintenance Guide

- Box Pallets & U-Drain Pallets: Essential Components in Modern Drainage Systems

BACK TO ARTICLES

BACK TO ARTICLES